FAQS

Best Warehouse Heaters for Energy Efficiency and Effective Heating Solutions

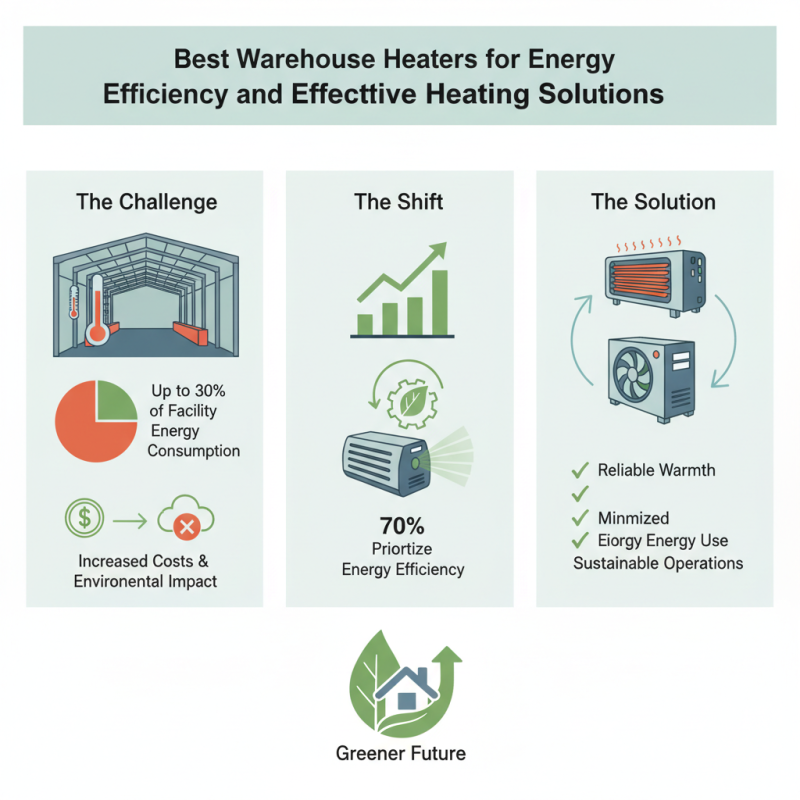

In today’s industrial landscape, the demand for energy-efficient heating solutions has become increasingly critical, particularly for warehouses that often encompass vast, open spaces requiring consistent temperature management. According to a recent report by the U.S. Department of Energy, warehouses can account for up to 30% of a facility's total energy consumption, with heating being a significant contributing factor. This highlights the pressing need for businesses to invest in effective and energy-efficient warehouse heaters to not only maintain optimal working conditions but also to reduce operational costs and environmental impact.

Moreover, as the logistics and manufacturing sectors continue to expand, an estimated 70% of warehouse operators are now prioritizing energy efficiency in their heating choices, as noted in a study conducted by the International Energy Agency. Modern warehouse heaters are designed to provide reliable warmth while minimizing energy use, thus facilitating a more sustainable operational approach. By understanding the available options and selecting the right warehouse heaters, businesses can significantly enhance their heating efficiency and contribute to a greener future.

Understanding Energy Efficiency in Warehouse Heating Solutions

When evaluating energy efficiency in warehouse heating solutions, it is crucial to understand the various technologies and designs that contribute to effective thermal management. Energy-efficient heaters utilize advanced heating methods, such as infrared technology or heat pumps, which allow for targeted heating systems that minimize energy waste. By focusing on heating only the essential areas, these systems reduce the overall energy consumption, leading to lower utility bills and a reduced carbon footprint.

Moreover, proper insulation and strategic placement of heating units within the warehouse can enhance energy efficiency. A well-insulated warehouse will retain heat more effectively, allowing for lower operational costs and improved comfort levels for employees. Implementing programmable thermostats and zoning systems further optimizes energy usage by allowing for tailored heating solutions based on occupancy levels and specific operational requirements. By employing these strategies, warehouses can not only achieve effective heating solutions but also significantly improve their energy efficiency.

Best Warehouse Heaters for Energy Efficiency and Effective Heating Solutions

| Heater Type | Energy Efficiency Rating (EER) | Heating Capacity (BTUs) | Fuel Type | Average Operating Cost (per hour) |

|---|---|---|---|---|

| Electric Infrared Heater | 95% | 5000 BTUs | Electric | $0.50 |

| Natural Gas Radiant Heater | 90% | 6000 BTUs | Natural Gas | $0.40 |

| Forced Air Propane Heater | 85% | 8000 BTUs | Propane | $0.55 |

| Convection Heater | 87% | 7000 BTUs | Electric | $0.45 |

| Oil-Fired Heater | 80% | 7500 BTUs | Heating Oil | $0.65 |

Types of Warehouse Heaters: A Comprehensive Overview

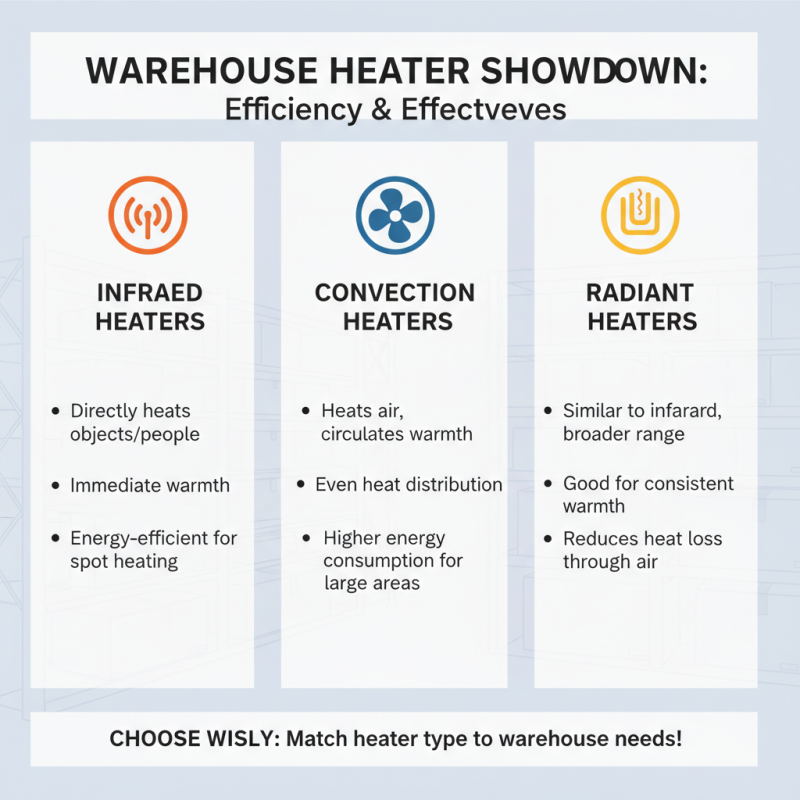

When considering heating solutions for warehouses, it's essential to understand the various types of heaters available and their energy efficiency. Primarily, there are three categories of warehouse heaters: convection heaters, infrared heaters, and unit heaters. Each type offers unique benefits and is suited to different operational needs.

Convection heaters, for instance, work by warming the air in the space and circulate it throughout the warehouse. According to a report from the U.S. Department of Energy, convection heaters can be highly effective in providing consistent overall warmth, particularly in larger spaces.

On the other hand, infrared heaters focus on delivering heat directly to objects and people within the warehouse, rather than warming the air. This method can significantly reduce energy costs since heat loss through ceilings and walls is minimized. The International Energy Agency (IEA) indicated that infrared heaters can improve heating efficiency by approximately 30% compared to conventional heating systems, making them an attractive option for areas with high ceilings and frequent door openings.

Additionally, unit heaters, often using a forced air method, can be quite versatile, allowing for rapid heating in specific zones of the warehouse, thus optimizing energy use.

Choosing the right type of warehouse heater can significantly influence operational costs and energy consumption. A comprehensive analysis of the heating needs and warehouse layout is crucial for selecting the most efficient heating solution. With proper evaluation, businesses can significantly enhance their heating effectiveness while minimizing energy expenditures.

Key Features to Look for in Energy-Efficient Warehouse Heaters

When selecting energy-efficient warehouse heaters, there are several key features to consider that can greatly impact both performance and cost savings. First and foremost, the heater's heating capacity should match the size of your warehouse. A heater that is too small will struggle to maintain a comfortable temperature, while one that is too large can lead to unnecessary energy waste. Look for units with adjustable thermostats and multiple heat settings for better control and efficiency.

Additionally, consider the type of fuel the heater uses. Electric heaters are typically more energy-efficient than traditional gas models, especially in well-insulated warehouses. Infrared heaters, for instance, warm objects and people directly rather than the air, reducing heat loss and allowing for lower energy consumption. Insulation plays a crucial role; enhance your warehouse's insulation to maximize the effectiveness of any heating system.

Tips: Regular maintenance is essential to ensure the efficiency of your heating system. Schedule periodic checks to clean filters, inspect heating elements, and make any necessary repairs. Furthermore, strategically placing heaters throughout the warehouse can optimize heat distribution, reducing cold spots and maintaining a consistent temperature across the space.

Comparative Analysis of Top Warehouse Heater Brands

When evaluating warehouse heaters, it is essential to perform a comparative analysis of various brands to identify the most energy-efficient and effective solutions. Different heating technologies, such as infrared, convection, and radiant heat, can greatly influence performance and energy consumption. Infrared heaters, for instance, typically provide immediate warmth by directly heating objects rather than the air, making them a popular choice for large, open spaces. Conversely, convection heaters circulate warm air throughout the warehouse, offering even heating but often consuming more energy.

Factors such as heating capacity, energy consumption rates, and installation requirements should be considered when analyzing top brands. High-efficiency models often incorporate advanced technology that ensures minimal energy wastage, which not only contributes to lower operational costs but also aligns with sustainability goals. Additionally, features like programmable thermostats and zone heating capabilities can enhance energy efficiency further by allowing precise temperature control based on specific operational needs. Ultimately, a comprehensive comparison allows warehouse managers to select heaters that best meet their heating requirements while maximizing energy efficiency.

Best Practices for Maximizing Heating Efficiency in Warehouses

Maximizing heating efficiency in warehouses is essential for reducing energy costs and ensuring a comfortable working environment. One of the primary strategies is to maintain optimal insulation throughout the facility. Proper insulation minimizes heat loss, allowing the heating system to work effectively without overexerting itself. Regularly inspecting and sealing gaps around windows, doors, and vents can significantly improve insulation levels, contributing to a more energy-efficient operation.

Tips: Consider using insulated curtains or covers during colder months to further reduce heat escape. Additionally, installing reflective barriers in ceilings can help direct heat downward, ensuring that warmth is concentrated where it is needed most.

Another best practice is to employ a zoning strategy for heating. By dividing the warehouse into sections that can be heated independently, you can conserve energy by not heating unused areas. This targeted approach allows you to adjust temperatures based on specific needs, leading to further efficiencies.

Tips: Utilize programmable thermostats to automate temperature adjustments based on occupancy patterns, which will not only enhance employee comfort but also reduce energy waste. Implementing these strategies will help ensure that your warehouse remains warm and energy-efficient throughout the colder months.

Energy Efficiency of Warehouse Heaters

This chart displays the energy efficiency ratings (in percentage) of different types of warehouse heaters. Efficient heating solutions can significantly reduce operational costs and enhance overall productivity.

Related Posts

-

Top 10 Warehouse Heaters Tips to Keep Your Space Warm Efficiently

-

Unlocking Warehouse Heaters Market Trends at the 138th Canton Fair 2025 in China

-

Ultimate Guide to Portable Heaters Top Tips for Efficient Heating

-

Maximizing Outdoor Comfort: The Ultimate Guide to Choosing Commercial Patio Heaters

-

Exploring the Science Behind Industrial Heaters: How They Transform Energy into Heat

-

Exploring Innovations in Gas Patio Heater Products at the 2025 Canton Fair

Skip to content

Skip to content