FAQS

How to Choose the Best Industrial Space Heaters for Your Needs?

Choosing the right industrial space heaters is crucial for any business. According to Dr. Emily Carter, an expert in heating solutions, "Selecting efficient heating makes a significant difference." Businesses often overlook the specific needs of their spaces. The right heater can enhance productivity and worker comfort.

When considering industrial space heaters, think about the size of your workspace. A larger area may need more powerful units. Efficiency is also key. Some heaters use more energy than others. This can lead to increased costs over time. It's essential to weigh these factors carefully.

Many overlook safety features as well. Certain models may offer excellent heating but lack essential safety measures. This can lead to risk in the workplace. Decide what is best for your team and operations. Reflecting on these aspects can ensure you choose wisely.

Understanding Different Types of Industrial Space Heaters and Their Applications

When selecting the right industrial space heater, it's crucial to understand the various types available. Electric heaters are popular due to their efficiency. They require a power source but provide instant warmth. These heaters work well in smaller spaces. They are usually quieter as they do not rely on combustion.

On the other hand, gas heaters offer robust heating capabilities. These are suitable for larger areas. They often heat up quickly, making them ideal for work environments. However, safety precautions are essential. Gas heaters require ventilation to prevent harmful fumes. Workers must be educated about potential risks.

Infrared heaters are another option worth considering. They directly warm objects and people rather than the air. This leads to energy savings in spaces that are not constantly occupied. However, they might not be as effective in large or drafty areas. It’s important to weigh the pros and cons when making a choice. Think about your specific heating needs, the size of the space, and any applicable safety measures.

Evaluating Heating Capacity: BTUs and Size Requirements for Your Space

Choosing the right industrial space heater requires careful evaluation of heating capacity. BTUs, or British Thermal Units, measure heating output. You need to know how many BTUs your space requires. A larger area needs more BTUs.

Generally, a small workshop may need about 5000 to 10,000 BTUs. A bigger warehouse might demand 20,000 BTUs or more. This calculation can be tricky. Factors like ceiling height and insulation influence the needed BTUs. Don't overlook windows and doors; they can lead to heat loss.

It's important to assess the heater's efficiency. Find out how many BTUs are used per hour. Some heaters have better energy ratings than others. However, energy costs can vary widely. If your budget is tight, consider the long-term costs as well. Reflect on your specific needs and make adjustments as necessary. The right choice can make a significant difference.

Heating Capacity Evaluation: BTUs Required for Different Space Sizes

Assessing Energy Efficiency Ratings: How to Calculate Operating Costs

When selecting an industrial space heater, energy efficiency is crucial. Many heaters are rated using the Energy Efficiency Ratio (EER). This puts heating performance in perspective. For instance, a heater with an EER of 10 uses 1 kilowatt to produce 10 kilowatts of heat. This metric can help you make informed choices.

Operating costs are a key factor. Understanding how to calculate these costs is essential. For example, if a heater consumes 5 kWh per hour, and your energy price is $0.12 per kWh, your hourly cost is $0.60. This seemingly low amount can rack up over time in larger industrial spaces. According to the Department of Energy, heating accounts for nearly 30% of industrial energy usage. This alludes to the importance of choosing energy-efficient models.

Real-life applications reveal inconsistencies. Some heaters may promise high efficiency but underdeliver. Regular maintenance is often overlooked, affecting performance. Users should adjust settings based on actual usage patterns to optimize costs. The balance between upfront costs and long-term savings is delicate and requires thought. A smart selection can turn energy savings into tangible benefits.

Safety Features and Regulations: Ensuring Compliance in Industrial Settings

In industrial settings, safety is paramount. Choosing the right space heater goes beyond comfort. It requires thorough consideration of safety features. Look for models that include tip-over protection, overheat shut-off, and sturdy construction. These features help prevent accidents and manage fire hazards. When heaters tip or get too hot, they can pose serious risks.

Compliance with local regulations is crucial. Make sure to check if your heaters meet required safety standards. Each industrial facility differs in space and ventilation needs. It is essential to ensure that the heater doesn’t obstruct emergency exits or create hot spots in confined areas. Are there sufficient guidelines on spacing from flammable materials? Being aware of these factors can help avoid costly incidents.

Continuous evaluation of equipment is necessary. Regular maintenance is often overlooked. Inspect your heaters periodically for wear and tear. Ask if the heater still operates efficiently. Sometimes, early signs of malfunction go unnoticed. It's important to address these before they become a bigger issue. Prioritizing safety and compliance is key in protecting lives and assets.

Key Considerations for Fuel Types: Electric, Gas, and Diesel Heaters

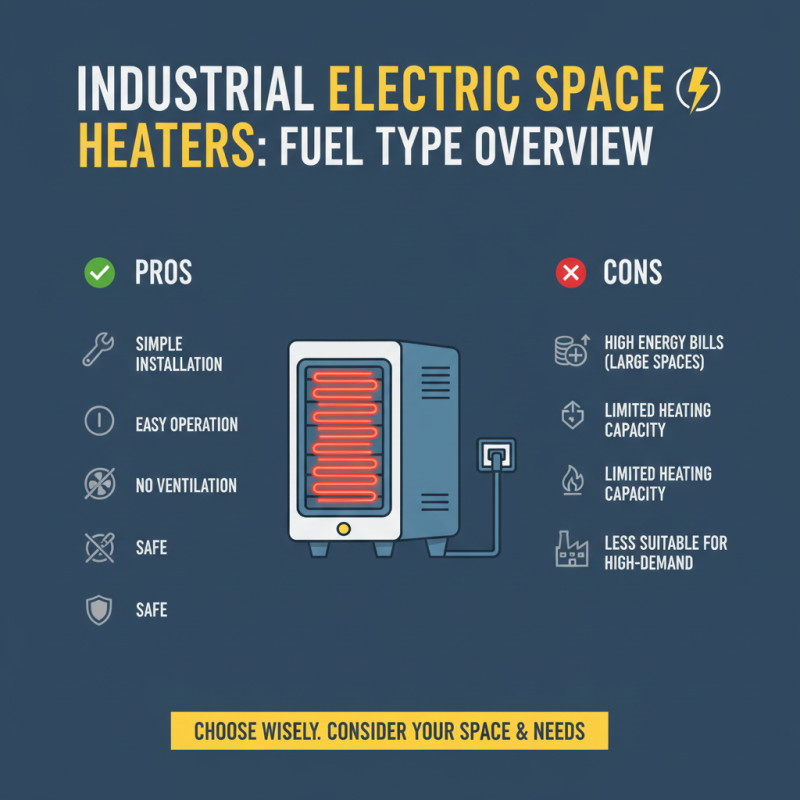

When choosing an industrial space heater, understanding fuel types is crucial. Electric heaters are often simple to install and operate. They do not require ventilation and are generally safe. However, they may lead to high energy bills, especially in large spaces. Their heating capacity can be limited, making them less suitable for high-demand environments.

Gas heaters, on the other hand, provide more powerful heating. They can quickly warm large areas and operate efficiently. They require proper ventilation, which adds to installation costs. Gas models can be less versatile, especially in spaces without gas lines. Consider local regulations on emissions and safety standards, as these can impact their usage.

Diesel heaters are a solid choice for remote or unserviced locations. They offer portability and substantial heat output. However, they require regular maintenance and can produce emissions that need managing. Their fuel storage can be a concern in terms of safety. Reflect on your specific needs and limitations. Each fuel type has pros and cons that require careful consideration.

Related Posts

-

Exploring the Science Behind Industrial Heaters: How They Transform Energy into Heat

-

Unlocking Warehouse Heaters Market Trends at the 138th Canton Fair 2025 in China

-

10 Best Portable Heaters for Effortless Warmth in Every Room this Winter

-

2025 Guide to Choosing the Best Industrial Infrared Heaters for Your Needs

-

10 Essential Tips for Choosing the Right Warehouse Heaters?

-

Why You Should Choose a Wall Mounted Infrared Heater for Efficient Heating

Skip to content

Skip to content