FAQS

Top 10 Warehouse Heaters Tips to Keep Your Space Warm Efficiently

As industrial and commercial activities continue to expand, maintaining optimal temperatures in warehouses has become a significant concern for business efficiency. According to the U.S. Department of Energy, nearly 30% of warehouse energy consumption is attributed to heating, highlighting the importance of effective temperature management. Warehouse heaters play a critical role in ensuring that products, equipment, and personnel are kept in a comfortable and safe environment, especially during colder months. However, the selection and utilization of warehouse heaters require careful consideration of energy efficiency and operational cost-effectiveness.

Recent studies indicate that investing in the right warehouse heaters can lead to significant energy savings, as high-quality heating systems can reduce energy consumption by up to 40% compared to older models. Moreover, the efficiency of these systems is not only beneficial for the bottom line but also contributes to a more sustainable and environmentally friendly operation. By implementing strategic heating solutions, businesses can enhance productivity while minimizing their carbon footprint. This article will explore the top 10 tips for choosing and utilizing warehouse heaters effectively, ensuring your space remains warm and efficient throughout the year.

Understanding the Importance of Efficient Warehouse Heating

Efficient heating is crucial for warehouses, which often face unique challenges related to maintaining a consistent temperature. Research shows that a significant portion of warehouse energy consumption—up to 30%—is attributed to heating costs, highlighting the need for strategies that optimize energy use. In colder climates, the temperature in a warehouse can drop to uncomfortable and even unsafe levels, potentially affecting worker productivity and the integrity of stored goods. Thus, understanding the dynamics of heating systems is essential for warehouse managers aiming to create a comfortable working environment while minimizing energy expenses.

Moreover, adopting efficient heating solutions can substantially reduce operational costs and contribute to sustainability goals. According to the U.S. Department of Energy, improving heating efficiency by as little as 10% can lead to savings of around $1,300 per year for average warehouse operations. Insulation, proper air sealing, and the use of infrared heaters or more advanced HVAC systems can make a significant impact on both energy consumption and thermal comfort. Evaluating these options not only ensures the well-being of employees but also aligns with broader corporate responsibility initiatives, underscoring the importance of efficient warehouse heating in today's operational landscape.

Choosing the Right Type of Heater for Your Warehouse Needs

When selecting the right type of heater for your warehouse, it's crucial to consider the specific needs of your space.

Different types of heaters offer various methods of generating heat, such as forced air, radiant,

or convection heating. Forced air heaters are ideal for larger warehouses as

they can quickly circulate warm air, raising the overall temperature effectively. On the other hand, radiant heaters are more suitable for spaces with high ceilings

because they deliver heat directly to objects and people, rather than heating the air, which can be more efficient in vast areas.

Another important factor to consider is the heater's energy efficiency and operational costs. Opting for electric or gas heaters can have different implications for your energy bills.

Additionally, it’s valuable to assess the insulation of your warehouse. A well-insulated space will retain heat more effectively, allowing you to choose a

less powerful heater while still maintaining a comfortable environment. Lastly, think about safety features and maintenance requirements,

as these will contribute not only to your comfort but also to the longevity and reliability of the heating system you choose.

Insulation Techniques to Enhance Heat Retention in Warehouses

When it comes to maintaining warmth in a warehouse, effective insulation techniques are crucial for enhancing heat retention and reducing energy costs. Proper insulation not only keeps temperatures stable but also contributes significantly to the overall efficiency of heating systems. Start by assessing the building’s existing insulation, focusing on walls, ceilings, and floors. Adding insulation materials, such as fiberglass or foam, can significantly reduce heat loss and create a more comfortable environment for workers and stored goods.

Sealing gaps and cracks is another vital step in improving insulation. Check doors, windows, and any other entry points for air leaks, as these can be major sources of heat loss. Using weather stripping or caulking can effectively seal these gaps, ensuring that warm air remains inside and cold drafts are kept at bay. Additionally, utilizing insulated curtains or thermal blinds can further enhance heat retention, especially in large spaces with extensive window areas. By investing in these insulation techniques, warehouses can achieve a warm and efficient space, ultimately lowering energy consumption and costs.

Warehouse Heat Retention Techniques Efficiency

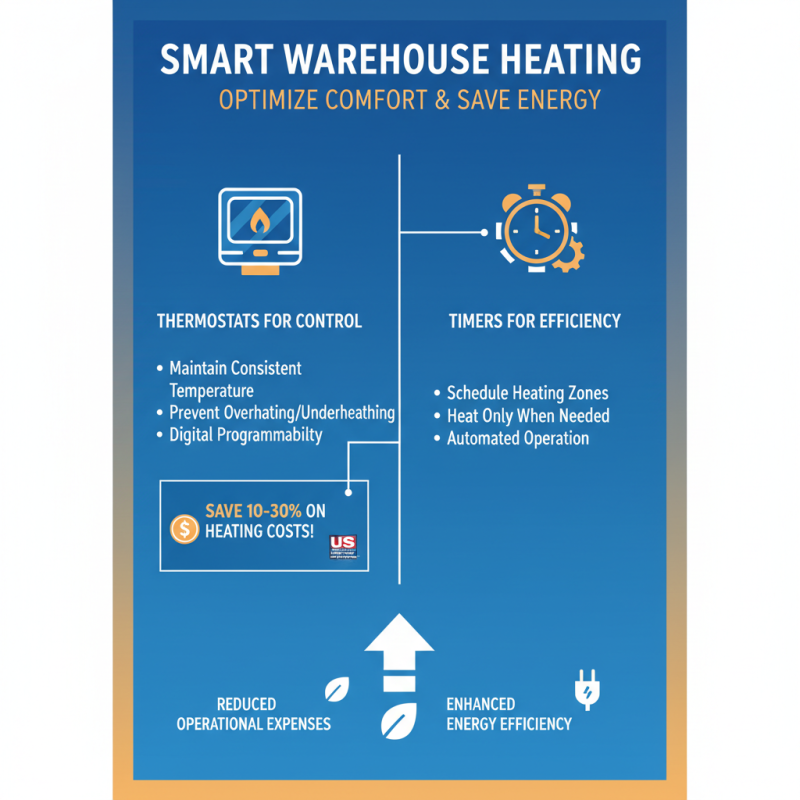

Implementing Thermostats and Timers for Optimal Heating Control

Effective warehouse heating is crucial for maintaining a comfortable environment, especially during colder months. One of the key strategies to achieve optimal heating control involves the implementation of thermostats and timers. According to the U.S. Department of Energy, a programmable thermostat can reduce heating costs by up to 10% to 30% annually, making it an essential tool for warehouse managers looking to enhance energy efficiency and reduce operational expenses.

By setting timers on heating systems, facilities can ensure that the heating operates only during necessary hours. For instance, programming heaters to turn on shortly before staff arrival and shut off after hours can significantly conserve energy. A study by Energy Star indicated that businesses could save approximately 60% on their heating costs by optimizing their heating schedules through timers. Additionally, integrating smart thermostats that adapt to real-time temperature changes can contribute to consistent comfort levels while preventing unnecessary heating during moderate weather.

Incorporating these systems also allows for remote monitoring and control, providing managers with real-time insights into energy usage. This data-driven approach enables proactive adjustments, ensuring that the heating system operates efficiently without overuse. Ultimately, effective use of thermostats and timers not only bolsters comfort but also plays a significant role in reducing a warehouse's carbon footprint and fostering sustainable practices within industrial operations.

Regular Maintenance Practices for Long-lasting Heating Systems

Regular maintenance practices are essential for ensuring the longevity and efficiency of heating systems in warehouses. According to a report by the U.S. Department of Energy, properly maintained heating systems can operate up to 15% more efficiently than those that are neglected. This efficiency translates to substantial cost savings over time, especially considering that warehouse heating can account for a significant portion of operational expenses. Regular inspections and system cleaning can prevent common issues such as dust buildup and mechanical wear, which are often culprits in reduced heating performance.

Furthermore, adopting a maintenance schedule that includes tasks such as filter replacements, duct cleaning, and system tune-ups can prolong the lifespan of the heater and reduce the likelihood of unexpected breakdowns. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) emphasizes that warehouses should aim for an annual inspection to assess the health of their heating systems, highlighting that proactive measures can lower repair costs by up to 40%. By investing in routine maintenance, warehouse operators not only enhance operational efficiency but also create a safer and more comfortable working environment for employees.

Related Posts

-

Exploring the Benefits of IR Panel Heaters: A Modern Solution for Cost-Effective Heating

-

“Unlocking Outdoor Comfort: The Ultimate Guide to Choosing the Perfect Deck Heater for Your Space”

-

Maximizing Outdoor Comfort: The Ultimate Guide to Choosing Commercial Patio Heaters

-

How Infrared Bar Heaters Work: The Science Behind Efficient Heating Solutions

-

Unlocking Industrial Efficiency: The Science Behind Infrared Heating Technology

-

Exploring Innovations in Gas Patio Heater Products at the 2025 Canton Fair

Skip to content

Skip to content